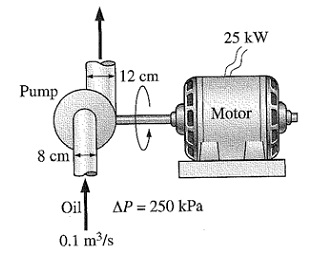

The oil pump is drawing 25 kW of electric power while pumping oil with ρ = 860 kg/m3 at a rate of 0.1 m3/s. The inlet and outlet diameters of the pipe are of 8 cm and 12 cm, respectively. When the pressure rise of oil in the pump is measured to be 250 kPa and the motor efficiency is 90%, then find out the mechanical efficiency of the pump. Taking kinetic energy correction factor to be 1.05.