Review the Extended Enterprise Supply Chain (EESC) from the attached paper. Identify in the EESC where each of the four modes of transportation are used: rail, inland water, ocean, and over the road trucking (OTR). Use topic headings for each mode. Identify the materials being transported from which industry to which industry. Include a diagram of the EESC. Discuss why this mode is being used and what the costs are on a per ton-mile basis. Use at least 6 references, cited. 3-4 pages in length.

Forecasting/EESC – Wilson Soccer Ball Company

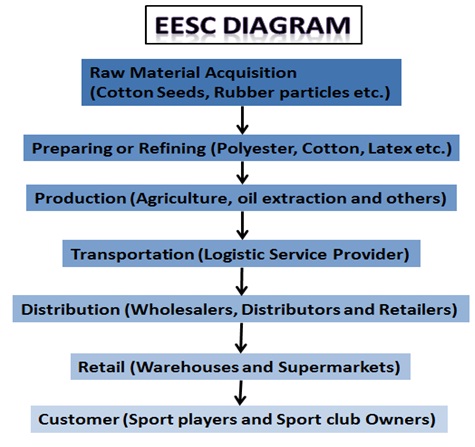

Extended enterprise supply chain (EESC) management is the best way to expand the wings of supply chain in the global world. Effective management of the supply chain provides various financial benefits to an organization like on time delivery, reduced overall costs and others. In this regard, the following discussion will focus on the Wilson Soccer Ball EESC to the raw materials that are the upstream production.

Backward Explosion:

The Wilson Soccer Ball products, in order to intensify its product, have taken an initiative in building the extended supply chain. In an extended supply chain, various supply chain partners collaborate on the behalf of trust, shared vision, and commitments to form an integrated supply chain. Basically, it helps an organization in expanding its value mission, cross system relationships and others (Davis & Spekman, 2004). The Wilson Soccer ball products are prepared with extreme care and planning so as to avoid any accidents of the players. Although it seems to be very simple, the ball has been composed of various synthetic materials like rubber, latex, polyester, cotton materials, microfiber and poly vinyl chloride are used in preparing the products that basically helps in minimizing the moisture absorption capacity and thus preventing the ball from becoming heavy. These materials generally come from the productions of Asia, China, Vietnam, and Pakistan. The panels of the ball are prepared by stitching with the use of polyester. The linings in the ball are made up by polyester or cotton lamination. Another component of the ball called a bladder is developed by latex, polyurethane or butyl (Soccer Ball World, 2015).

Forward Explosion:

The soccer manufacturing industry runs on a large scale production because of high demand during the seasons of the World Cup and is responsible for contributing towards child labor extensively. The major players of the soccer industry are experiencing a stuck feeling between greater production costs and penny-saving customers. In addition to this, the greater fluctuations in demand also contribute towards the uncertainty in the industry (The Economist, 2000). The Wilson Soccer Ball company has its distributors, wholesalers and retailers as buyers. In addition to this, its customers include the soccer players and sports clubs established at various institutions. As the resources and raw materials are obtained, the manufacturing process of the soccer ball begins. Once the balls are manufactured, they are sent for testing of quality standards. After the passing of required tests, the goods are transported to the company's distributors and the logistics partner of the distributor is responsible for storing and managing the products.

Thereafter, the products are to obtain the clearance of the customs department in order to transport it further towards the retailers through the medium of land, air or water transport. The logistics service provider has an additional role when the goods reach their selling location or destination (Puzey, 2014). The products are then unloaded from the carriage of particular transportation medium used by the company and sent to a warehouse for verification of products before the final distribution. The verified products are then packed and sent to the local distribution centers, which are responsible for selling the products to retail stores and online-store warehouse and fulfillment centers. After the receipt of the products by the retailers and online-store warehouses, the products are re-packed and checked before delivering it to the customers (Puzey, 2014). The types of retail businesses for global companies are dependent upon the business structure and the selling method. The types of retail businesses include departmental store, warehouse-based retailer, supermarkets, specialty stores, discount retailers, convenience stores and e-retailers (The Reseller Network Ltd., 2010). The company uses maximum types of retailers in order to make the reach of its product easily in a wider market. The Wilson Company also sells its product through an online medium such as their company website and other electronic retail websites such as Amazon, Sport Sally and Wal-Mart.

The packaging of the ball is done by using silk screening over the cover materials. Moreover, in order to protect the print made on the ball, an extra protection of clear urethane is also provided. Additionally, in packaging of Soccer balls a different variety of needle is used so that signs of stitching disappear (Soccer Ball World, 2015). These materials are produced by different processes like latex is produced from rubber tree and is developed by the agricultural process. The raw materials required for this production are rubber particles, water, proteins, resins, ash and sugars. Similarly, polyester is produced through the process of oil extraction and has the raw material as ethylene. The cotton has been produced by agriculture process by using cotton seeds as the raw materials. In addition to this, polyvinyl chloride is obtained from raw materials called as ethylene and chlorine through polymerization (Made How, 2015).

Various industries with their locations have been discussed that possess an Extended Enterprise Supply Chain (EESC) system. Furthermore, discussions have also been made with regard to specific challenges in this system like legalities, shortages and technological change. The various industries that have adopted the Extended Enterprise Supply Chain system are IBM, Proctor & Gamble, Wal-Mart, FedEx and Dell to name a few. In the United States, the location of the company of Wal-Mart is in Arkansas, whereas IBM and Dell are located in New York City and Texas respectively. P&G and Fed-Ex are located in Ohio and Tennessee respectively.

With regard to EESC, there are a few challenges faced by the companies that have adopted this system. The issues faced by the companies are in the form of legality issues such as consideration of human rights at a global level (Coon et al., 2014). In addition to this, the EESC also faces the issue of disturbed logistics due to which the global supply chain of the company is also affected (Márquez, 2010). Furthermore, the EESC system also faces the issue of coalition of technological strategy within the system (Pappis, 2010).