1. What potential problems (to the pump and the pipe) exist when a pump is started and the pipe is empty?

2. Explain the process and list the factors that need to be considered to decide if it is cheaper to build one pipe at the present time to handle needs for 50 years or if it is cheaper to build one pipe now and another later.

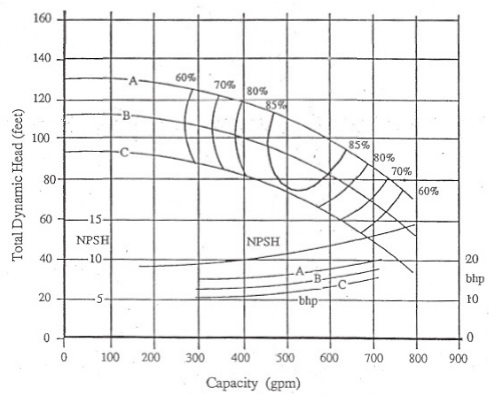

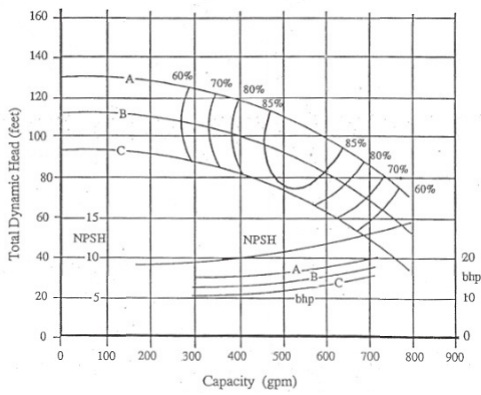

3. Using the pump curve provided below and the following system equation, find the flow rate for one pump A installed in parallel with a Pump B. List the head, flow, bhp, efficiency, NPSH for each pump when they are operating individually and together (ie; list three sets of data). Identify the operating points on the figure and show your work.

System Equation: Hp = 60 ft + 0.0000533 Q2 (Q is in gpm)

4. Using the same pump curve an data from problem 3, if the standard rotational speed of the pumps A is 1750 rpm, how fast should the pump rotate if you want 1/2 of the flow of pump A operating by itself? You can use the graph or a spreadsheet to determine.

General Information:

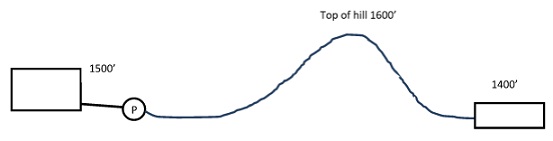

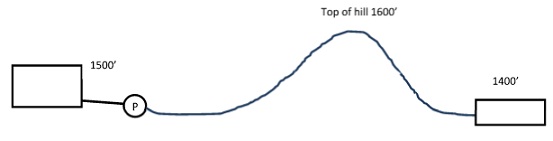

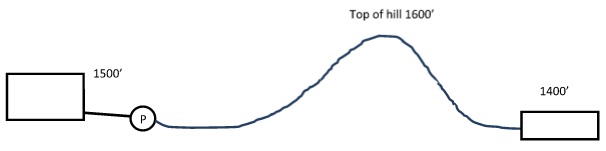

You are designing a pipeline and using a pump for the following system. The water surface elevation of the upstream reservoir is 1500 ft and the downstream water surface elevation is 1400 ft. A hill is located between the two reservoirs and has a top of hill elevation of 1600 ft. Pipe length to the top of the hill = 3000 ft. From the top of the hill to the downstream reservoir has a pipe length = 1000 ft. The system needs 6000 gpm and it is commercial steel pipe. The water temperature is 50oF. Minor losses include the entrance and exit.

5. If a single pipe diameter was selected describe how the system would operate (include filling and emptying). Would a pump be required? Is anything needed at the hill to make the system operate properly? (no calculations are needed for this answer).

6. if a single pipe diameter is to be used what size would you recommend? Clearly state any assumptions that you make in your design and draw the HGL on the system diagram.

7. Based on minimizing pipe cost:

a) Why or why not would you want to use the same diameter pipe on both sides of the hill?

b) Assuming that two different pipe sizes were to be used. Select reasonable pipe diameters, recognizing that a pump will be needed to get the water over the hill. You can select from a choice of 10, 12, 14, 16, 18 and 20 inch ID pipe. Remember, the pipe is empty when constructed or drained and must be filled. Clearly state any assumptions you make show calculations you used for selecting each pipe.

8. Draw the HGL for the system with 2 different pipe sizes.

9. Rather than use 2 pipe sizes, you decide to use one 16-inch diameter pipe and install a valve at the end of the pipeline near the 1400 ft tank to keep the pipe full. Assume that the flow Q = 6000 gpm.

a) Assuming that the pump lifts the water so that the HGL is exactly at the top of the hill, determine the required headloss across the valve to maintain full-pipe flow.

b) Assuming that the valve is a 12-inch (type A) butterfly valve, find the discharge coefficient (Cd) and the valve opening (%).

c) If the butterfly valve was opened to 50% but the flow remained at Q = 6000 gpm, determine the pressure drop across the valve and the required torque.

10. List three important hydraulic characteristics of check valves.

11. Explain the physics involved in deriving the torque coefficient equation. In other words, why is the torque proportional to d3 and ΔP? Drawing a sketch if it would be helpful. The equation is given as T = Ctdp d3 ΔP

12. What system and valve hydraulic characteristics make a valve a good control valve?

13. List the steps need to evaluate if a valve is a good control valve.