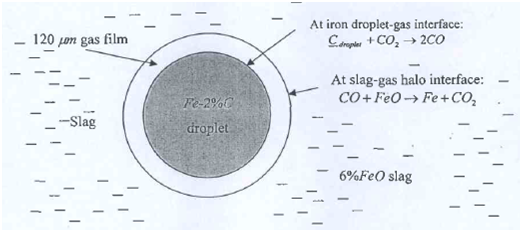

In the direct steelmaking reactor based on the reduction of an oxidizing foaming slag by char (carbon) particles and droplets of iron containing 2% carbon, it is postulated that the rate controlling step governing the reduction of FeO within the slag is the transfer of CO and CO2 across gas halos surrounding the iron droplets and char particles. In 4/S/ plant trials, the smelting rate of iron was observed to be 4 tonnes./hr of Fe. for a slag FeO content of 6 wr%, and a slag weight of 40 tonnes. Estimate the total surface area of char and iron droplets needed to achieve the smelting rates observed. Assuming the average char and droplet diameters to be 1 cm, estimate the volumetric loading (i.e. volume percentage) of droplets and char corresponding to these smelting conditions. State any assumptions you sec fit.

Data:

Atomic weight of Fe 56 g/mol

Gas constant, R : 8.314 J/mol.K

Temperature of Foaming Slag : 1600°C

Volume %CO2 in gas phase halos at slag interfaces : 6%

Gas pressure within halos : 1.2 mm

Gaseous Diffusion Coefficients (Da, = Day ) : 1.0x to") m2/s

Density of molten slag 3300 kg/m3