Assignment:

Case Study 1

Intercity Transportation Company Incorporated specializes in transporting bottled beverages. The company is currently experiencing difficulty in moving pallet loads of bottles from railroad cars into trucks.

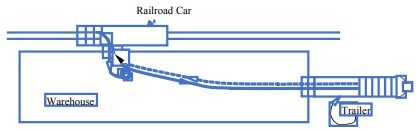

At the present time a 24-hour (3-shift) operation is maintained. Empty bottles arrive at the plant in railroad cars - three pallets wide in the car. The pallet size is 32" x 37" (block). The pallets are stacked in the railroad car on the 32" side and must be loaded into the trailer on the 37" side. The handling of pallets from the car to the trailer is performed by fork truck. There is a constant supply of railroad cars and trailers.

Handling Operation

The fork truck picks up a pallet in the rail car (0 ft. - 1.5 min.), moves to an open area in the warehouse (20 ft. - 1.25 min.), and drops the load. Backing out of the load entering and picking up the load form the other direction (0 ft - 0.75 min.), the load is then moved to a waiting trailer (30 ft. - 0.30 min.) and the load is placed into the trailer (20 ft. -0.30 min.). The fork truck then returns to the railroad car and picks up the next pallet load (70 ft. - 2.00 min.). This operation is repeated for each pallet load. A trailer load is 26 pallets and the railroad car contain 39 trailer loads. The present load patterns in the railroad cars and trailers cannot be changed.

Question:

1)- Determine the time to place a pallet into the trailer. Using the calculated time as a base time suggest methods for improving the operation.

2)- Determine Inventory accumulation in the warehouse per week and space required for the weekly inventory under the following conditions:

A)- If there is constant supply of railroad cars and truck.

B)- On average there is an average of half hour time between arrivals of consecutive trucks and the overall efficiency of the operations is about 95%

C)- List at least 4 areas for improvement (Speed up) of the operations

Case Study 2

The A-B Manufacturing Company receives cans used to package their fruits in re-shipper cartons. These cartons cannot be reused and are sent to a paper baler where they are baled and in turn placed in a railroad car.

Six freight handlers earning $5.25 per hour remove from the paper baler a bale of compressed cartons. Each bale is 33" x 46" x 84" with a weight of 735 lb. Each bale is wire-strapped. The six freight handlers remove the bale from the baler and place it on a four-wheel hand truck. All six handlers pull and push the truck to the railroad car where they place it into the car. This operation is repeated until the car is loaded. The capacity of the railroad car is 30 bales for a standard 40'6" car with a 6'8" wide door. Eight hours per day is a standard work shift.

The handlers have a 20-minute lunch and 20 minutes for coffee leaving a total of 440 minutes remaining for operational work.

Question:

1)-How can you make this operation more efficient using modern material handling methods? Do not consider the loading of the baler as part of the problem. Also, the location of the baler cannot be changed.

2)- Suggest 5 possible improvement to this system.

Attachment:- Case Studies In Material handing Systems.rar