Learning Outcomes:

1. Able to communicate effectively on material selection with material scientists

2. Able to understand the implications of different modes of material failure

3. To understand the effects of composition and heat treatment on the properties of different types of material

4. To select materials to minimize the likelihood of component failure

Problem 1:

Intermach Engineering Ltd is a high-quality manufacturer of precision machined components, utilizing leading edge CNC machining technologies. Intermach Engineering Ltd wants their designer engineers to select a new material for crank shaft used in the newer version of the Ford company four wheelers.

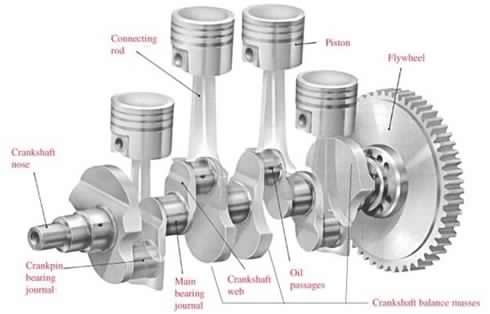

Crankshaft is a rotating shaft which (in conjunction with the connecting rods) converts reciprocating motion of the pistons into rotational motion (Figure 1). Crankshafts are commonly used in internal combustion engines and consist of a series of cranks and crankpins to which the connecting rods are attached.

Figure 1: Material selection for crankshaft

In order to select the material for the crank shaft you need to discretise crank shaft into smaller components. You can select any two parts in the crank shaft and for the decided parts select new materials.

Use CES EduPack to create a graph representing the material index and identify the region of the chart with the best materials for the selected parts.

You will need to decide your objective, constraints and find out the equations for the parts selected. You will need to translate the problem, derive the performance index or indexes, select some screening constraint and select the actual material graphically.

You have to document the whole selection process.

[Hint 1]: You need to select any two parts of the crank shaft and use corresponding equations for the selected parts to derive the material index. You will have to decide your own dimensions for the selected parts and the constraints.

Problem 2:

You have been asked to design a beam structure for the construction of the railway overhead platform in Nottingham Railway Station. The new overhead platform needs to withstand the moving traffic, pedestrian movements, heavy loaded trucks between the Station street and Nottingham Railway Station. The designers need to consider lightweight materials with maximum strength to weight ratio and build the structure as cheap as possible. Length, L and stiffness, S of the beam is fixed by the designer. The beam must deflect through a maximum safe displacement, δmax without failure.

Use CES EduPack to create a graph representing the material index and identify the region of the chart with the cheapest materials for the beam.

You will need to decide extra constraints and find out the equations for a beam. You will need to decide your objective and to compare the results with real world materials. You will need to translate the problem, derive the performance index or indexes, select some screening constraint and select the actual material graphically.

You have to document the whole selection process.

Problem 3:

CPE Pressure Vessels Limited Company manufacturers pressure vessel for oil, gas, petrochemical, nuclear and water industries. As a design engineer of the CPE company you have been asked to design a pressure vessel for the food manufacturing industry. The main objective of the work is to select a suitable material for the outer wall of the pressure vessel. When the pressure vessel is fully assembled it resemble as a cylindrical shape having an external pressure, p. The design of the outer wall of the cylindrical pressure tank and the selected material should resist the external pressure. The radius of the pressure tank is 10 m. The outer wall containing the pressure, p should not fail either by yielding or by fast fracture. The size of the possible largest crack contained in the outer wall is ac.

Most of the pressure vessels are made of high strength alloy steel, and they are heavy. You are asked to explore the potential of alternative materials for lighter pressure vessels, recognizing there must be a trade-off between mass and cost - if it is too expensive, the manufacturing company will not want it even if it is lighter.

Materials properties that are available for ranking materials are: density (ρ); Yield strength (σy); Critical stress intensity factor or fracture toughness of the material (KIC). The volume of material can be evaluated with respect to the surface area and the thickness of the cylindrical outer wall.

You will need to decide your own dimensions, extra constraints and find out the equations for yielding and fast fracture of the pressure vessel. In order to translate the right material selection for the food processing application into a real engineering problem you need to answer the following questions:

(a) Translation of problem indicating function, objective, constraints and free variables?

(b) Derive the performance material index for failure.

(c) Discuss the implication of two performance index for the selection of one material. Find the coupling line by making equal the cost calculated with the two indexes.

(d) Show that the mass and material cost of the pressure vessel relative to one made of high strength alloy steel is given by

m/mo = (ρ/σy)(σy,0/ρo) and c/c0 = (cmρ/σy)(σy.o/Cm,0ρ0)

where ρ is the density, σy the yield strength and Cm the cost per kg of the material, and the subscript "o" indicates values for high strength alloy steel.

Problem 4:

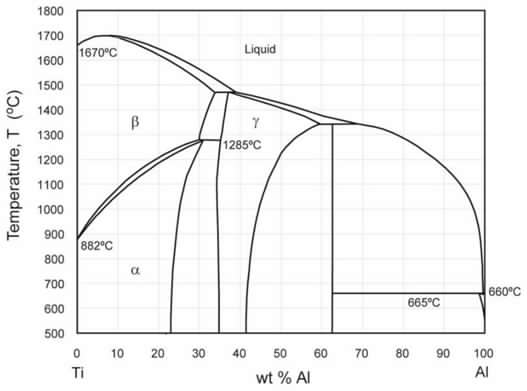

Figure 2 shows the Ti-Al phase diagram (important for the standard commercial alloy Ti-6% Al-4% V).

(a) List out all single-phase fields.

(b) Ring the three peritectic points, and one peritectoid point.

(c) One intermetallic compound can clearly be identified - what is its formula (atomic weights of Ti and Al are 47.90 and 26.98 respectively)?

(d) One single phase field spans a wide temperature range with a moderate spread of composition, and with one edge of the field being approximately a vertical line. Identify this limiting composition in weight percentage and assess whether the single phase may be considered to be a solid solution based on an intermetallic compound at this composition.

(e) At what temperature does a Ti - 6 weight percentage Al alloy start to melt?

(f) Over what temperature range does it change from α (HCP) to β (BCC)?

Figure 2: Titanium - Aluminium (Ti-Al) phase diagram

Problem 5:

a. Draw the Time Temperature Transformation T-T-T diagram for plain carbon steel of eutectoid composition and show on the diagram the critical cooling curve, the transformation lines, the phases, the axis.

b. With the help of T-T-T diagram for eutectoid plain carbon steel answered in part (a) explain following parts

(i) Explain the process to quench a component to obtained full retained austenite. Indicate the temperature and times needed in the process.

(ii) What are the phase or phases resultant from the following process? Keeping a component made of eutectoid plain carbon steel at 750 °C for one hour and then cooling it to 450 °C temperature in 1 second, keeping it at that temperature for 10 seconds and cooling it to room temperature in another 10 seconds.

(iii) What are the phase or phases resultant from the following process? Keeping a component made of eutectoid plain carbon steel at 750 °C for one hour and cool it down to 300 °C, keeping it at that temperature for 10 seconds and cooling it to room temperature in another 10 seconds.

Problem 6:

REIDsteel have designed and constructed a number of steel bridges nationally and internationally as per the British Standard 5400 Highway Bridge Loading Specification or other National Codes. One of the bridge constructed by REIDsteel in UK has developed the problems of corrosion as seen in Figure 3. Suggest three strategies to prevent/reduce the corrosion in the bridge after replacement of the corroded components by replacements made of the same material as the original material. Justify your choice with examples and discuss their advantages and disadvantages.

Figure 3: Corrosion of steel bridge

Problem 7:

(a) Using suitable examples, explain the meaning of dislocation movement in metals. Explain with simple sketches different types of dislocation in relation to metals.

(b) Using suitable industrial examples, explain creep in metals. Comment and contract dislocation movement in both plastic deformation and in creep.

Need A Reliable Advanced Materials and Materials Selection Assignment Help At Affordable Prices? Hire Apt Tutors To Score Top Grades!

Tags: Advanced Materials and Materials Selection Assignment Help, Advanced Materials and Materials Selection Homework Help, Advanced Materials and Materials Selection Coursework, Advanced Materials and Materials Selection Solved Assignments

Attachment:- Advanced Materials and Materials Selection.rar