OPERATIONS OF PUMP PERFORMANCE

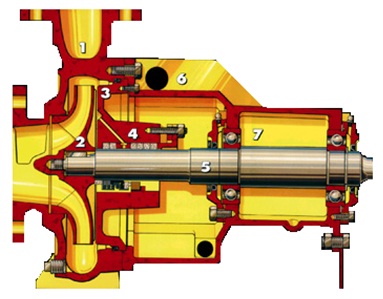

Q1. Name the components numbered in the sketch of a centrifugal pump.

Q2(a) A compressor installed at a whalf (for loading container ships) is able to provide 6 bar.g pressure into the pressure reciever. The compressor is moved to a site that is 5000 ft above sea level (atmospheric pressure 0.85 bar.a) in the mountains. What is the discharge revised discharge pressure (guage pressure) of the compressor ?

(b) Is the assumption of change in temperature valid for calculating the discharge pressure of the compressor ?

(c) The temperature at the whalf is 35oC and in the mountains is 19oC, what is the reduction in volumetic output from the compressor?

Q3 In your own words, describe why gland packing should have some small amount of leakage.

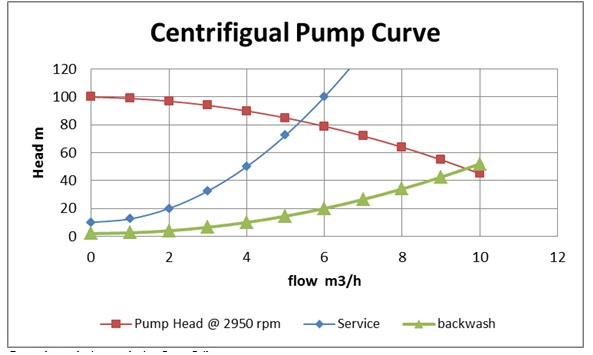

Q4. The system on site is a pressure sand filter, with a service curve. The filter is backwashed using the feed pump, at a higher flow rate, shown as backwash curve.

Service duty point : 3 m3/h

Backwash duty point : 9 m3/h

(a) What is the speed of the pump to achieve the service and backwash flow rates?

(b) What would be the best way to control the speed of the pump? Why?

(C) The pump is set up as a fixed speed constant pressure system (pump runs once system pressure reaches 550 kPa, turns off, when pressure drops to 450 kPa plant re-starts) to maintain a system pressure of 500 kPa at the discharge of the pump. What would be the service and backwash rates from the pump?

Q5. A pump station has been designed to lift water out of a 6 metre deep pit (vented to atmosphere) via a centrifigual pump mounted at ground level.

Liquid conditions 20OC

Suction pipe work losses 2.0 metres

NPSH safety factor 5.0 kPa

Vapor pressure @ 20oC 0.25 metres

(a) Calculate the Net Positive Suction Head (NPSH) for the system ?

(b) In summer the liquid temperature rises to 60oC, this changes the water vapor pressure to 2.05 metres. What is the revised NPSH for the higher water temperature ?

( c) Pressure loss in the suction pipe work is directly proportional to water veloicty in the pipe work squared, which is inversely proportional to suction pipe work diameter squared.

Q6. This definition is from your course notes

If suction of the atmospheric air (0 kg/cm2-g) is considered, devices that can develop pressure to 0.1 kg/cm2-g are called fans. Blowers are stronger and can build a pressure to 0.9 kg/cm2-g. Pressurizing devices above this range are called compressors.

Based on this definition, and the following data:

• 1 kg/cm2 – gauge = 1.01325 bar g

• 1 bar = 10 metres of water column (approx)

Are the following fans, blowers, compresors or something else:

• a hand held hot air gun

• the fan on a radiator of an engine

• a bicycle pump that can fill a tyre to about 2.75 barg (about 35 psig)

• a Helicopter (rotor on top)

• an engine turbo-charger

• gas combustion turbine

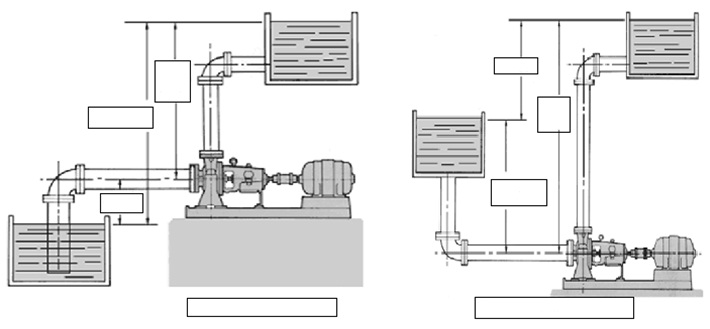

Q7.In the following figures, identify (a) Suction lift (b) Suction head and fill in the blanks

Q8. We have a compressor that has two problems … the engine is constantly loaded to maximum, and the life of compressor valves is short. It is suggested to reduce the lift on the compressor valves.

i) what problem would this help?

ii) in your own words, why would this help?

iii) what problem would this make worse. Hint … there are only two problems with this compressor, so the correct answer should be the other one

iv) in your own words, why would this make the problem worse?

Q9 You run a pump hire company and have the following pumps available for hire :

A. Helical rotor positive displacement pump maximum pressure 40 bar

B. Centrifugal pump BEP 30 m3/h @ 50 metres

C. Piston pump rated pressure 150 bar

D. Air operated diaphram pump, maximum flow 20 m3/h

You open, and the following customers come into the warehouse in the following order to hire a pump. You are to provide each customer with a suitable pump, note once a pump has been hired it is no longer available for hire to future customers. You can assume that the customers have the required utilities to run any of the pumps available.

1. Customer 1 – need a pump for recircultating lubrication oil (at variable temperatures)

2. Customer 2 – need a pump for sludge pumping

3. Customer 3 – need a high pressure pump to pump salty water into a reverse omosis system

4. Customer 4 – transfer of clean water from tank to truck

Allocate a pump to each one of the customers and breifly explain your selection

Q10. We have a reciprocating compressor operating at 800 rpm. Suction pressure and discharge pressure are held constant by other systems that have nothing to do with the compressor. We increase the speed from 800 to 840 rpm (a 5% increase).

• Part a what is the change in flowrate through the compressor Flow increases by (840/800) or 1.05, or 5% increase.

• Part b what is the change in pressure rise through the compressor.

• Part c what is the change in power that must be delivered to the compressor

Q11. We are operating a centrifugal compressor. The gas composition does not change during this excursion. While holding suction pressure and flow rate constant, the inlet temperature rises. What would you expect to happen to the discharge pressure, and why

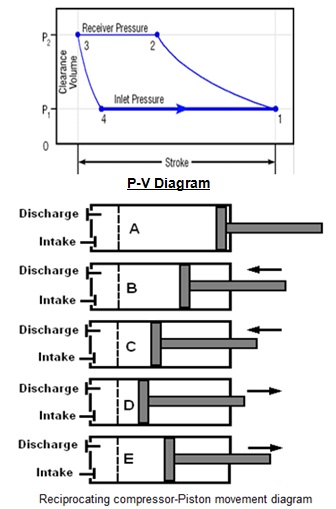

Q12. Compression occurs within the cylinder as a four-part cycle that occurs with each advance and retreat of the piston (two strokes per cycle). The four parts of the cycle are compression, discharge, expansion and intake. They are shown graphically with pressure vs. volume plotted in what is known as a P-V diagram. Identify the sequence in the reciprocating piston movement diagram.

Q13. With many lube oil systems, it is common to cool the oil before it is pumped to the end user (engine, compressor, etc). However, for large centrifugal compressors, it is common to pump the lube oil hot, and cool the oil immediately before it enter the compressor. Since we know that cool oil extends the life of the lube oil pump, why would we do this?