Question 1

The Norwitch Company uses a continuous review (s, Q) system for inventory control. Weekly demand for an item, Pressure Valve #5 (PV5), is distributed Normally with a mean and standard deviation of 20 and 10 respectively. Norwitch uses an order quantity of 200 units for PV5 and its supplier takes 5 weeks to fill an order. Each unit of PV5 costs $50 and carrying charges are $0.20/$/yr. Norwitch uses a 99% fill rate as a target service measure.

(a) Calculate the reorder point, s, that will satisfy Norwitch’s target fill rate. What is the likelihood that Norwitch has stocked out of PV5 when a new shipment arrives from its supplier?

(b) Assume Norwitch has worked out a new contract, accepted by all its customers, of being allowed up to one week to satisfy each demand. Norwitch still uses a 99% “fill rate” as a target service measure. However, stockouts satisfied within a week is considered as good as demand satisfied from the on-hand inventory.

How will you change the logic of computing the re-order point, s, to take account of the one-week grace period? Sketch the average behavior of the (s,Q) system to illustrate your reasoning.

(c) Calculate the reorder point for the new contract. What is the safety stock? On an average, how much inventory Norwitch has on hand when a new shipment of PV5 arrives?

(d) Estimate the annual cost savings due to the one-week grace period.

(e) What will be the impact of one-week grace period on Norwitch’s customers? Should Norwitch and its customers make the inventory status of PV5 known to each other? What good will that do? Question 2

Columbia Bookstore buys a popular freshman physics book at $30 each and sells it to students at $50 each. The same book is used for Fall and Winter terms. The demand for books is distributed Normally with a mean of 150 and 200 for Fall and Winter terms, respectively. The standard deviation of demand is 50, for Fall as well as Winter terms. The demand for each term can be assumed to be independent.

The publisher comes up with a new edition every year, making the old edition of the book worthless. The Bookstore simply throws away any leftover books at the end of the academic year (Winter Term). You have been asked to help the Bookstore in its purchasing decision for Physics books.

(a) Suppose the Bookstore used a newsvendor model to order books for each term. How many books should they order for Fall term and for the Winter term?

(b) Bill Nye, the new purchasing guy, at the Bookstore thinks one can just use the total demand for the year and make one purchasing decision for the whole year. How much should he order using this reasoning? Why this order quantity is different than the sum of order quantities computed separately for Fall and Winter in part (a)?

(c) What would YOU recommend to the bookstore? Propose an ordering policy (with numbers, if you can) and explain why this is a better alternative. Is your policy the best one can do? Why (not)? Question 3

Manufacturing glass for the iPhone revived a Corning factory in Kentucky, and today, much of the glass in iPhones is still made there. After the iPhone became a success, Corning received a flood of orders from other companies hoping to imitate Apple’s designs. Its strengthened glass sales have grown to more than $700 million a year, and it has hired or continued employing about 1,000 Americans to support the emerging market. But as that market has expanded, the bulk of Corning’s strengthened glass manufacturing has occurred at plants in Japan and Taiwan.

“Our customers are in Taiwan, Korea, Japan and China,” said James B. Flaws, Corning’s vice chairman and chief financial officer. “We could make the glass here, and then ship it by boat, but that takes 35 days. Or, we could ship it by air, but that’s 10 times as expensive. So we build our glass factories next door to assembly factories, and those are overseas.”

“How the U.S. Lost Out on iPhone Work,” The New York Times, January 21, 2012

Compare Corning’s decision to locate its factories in Asia to Lenzing’s decision to locate rayon fiber production in Indonesia. What are the similarities and differences?

Question 4

Saki, a local bar, consumes Mehboob, a popular non-alcoholic drink, at a steady rate of 10 cases/week. Saki usually buys Mehboob at $6/case, delivered to its door. However, the supplier is currently offering a promotional price of $5/case.

(a) If the carrying cost for Mehboob is $0.25/$/year, how many cases should Saki buy to take advantage of this promotion? Assume that the current promotion may end any day and that the next promotion is unlikely in foreseeable future. Indicate any other assumption(s) that you make for your analysis.

(b) How will your decision in part (a) change in each of the following cases?

i. If you had reasons to believe that your supplier gives this promotion annually;

ii. If you had reasons to believe that your supplier may give this promotion again sometime between six months to a year from now, equally likely;

iii. To eliminate the ill-effects of forward buying, your supplier allows you to order any quantity you like, but delays the delivery until you actually need it.

Question 5

How is the JIT II program at Bose Corporation related to the JITD initiative at Barilla SpA? What are the fundamental similarities and differences between the two programs?

Question 6

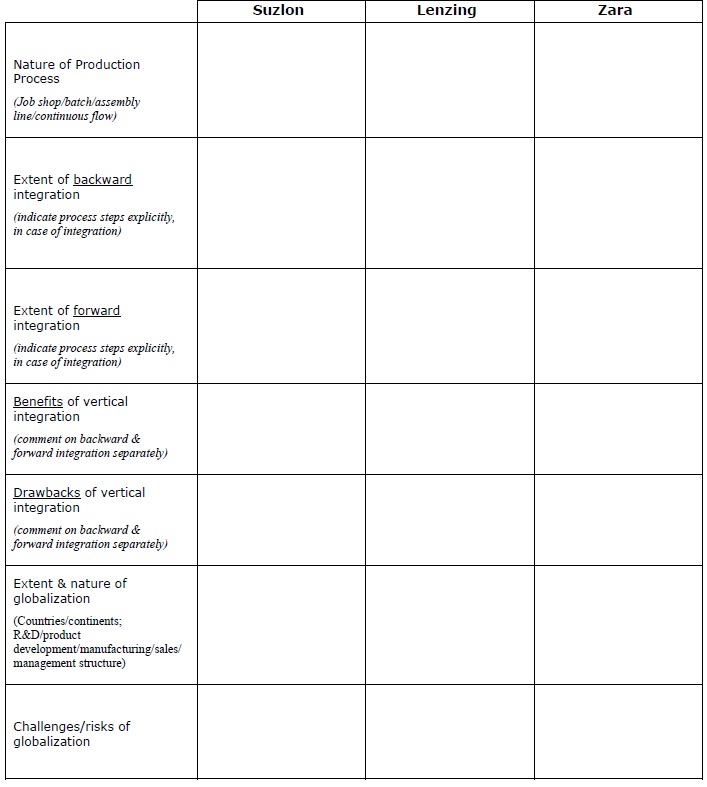

Compare Suzlon, Lenzing and Zara on the following dimensions (indicate key words):