Assignment:

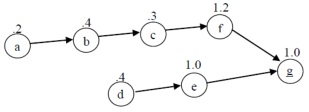

As part of a major plant renovation project, the industrial engineering department has been asked to balance a revised assembly process to achieve an output of 300 units per day (each day has 8 working hours). Task times (in minutes) and precedence relationships are as follows:

a. If there are 7 workstations, and each task is assigned to a workstation, what is the cycle time for this process? (Note that this cycle time is the minimum possible cycle time that can be achieved.

b. If all tasks are assigned to only one workstation, what is the cycle time of this process? (Note that this cycle time is the maximum possible cycle time that can be achieved.)

c. To achieve an output level of 300 units per day, what is the required cycle time?

d. Determine the minimum number of stations needed using the cycle time computed in part c.

e. Compute the positional weight of each task in the precedence diagram. Then assign the tasks to workstations based on the greatest positional weight. (If there is a tic between two tasks, you can arbitrarily choose one.)

Compute the efficiency of your design. Hint: to compute the efficiency, consider the cycle time of your design versus the maximum possible cycle time that can be achieved.