Problem:

Linear Programming of Manufacturing

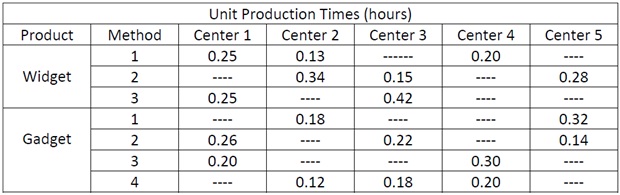

PDQ Manufacturing Company produces two products, widgets and gadgets. To produce each widget and gadget requires several basic machining operations. PDQ has five different machining centers, and some of the required machining operations can be performed at more than one of the centers. Consequently, there are several alternative methods ways of producing each widget and each gadget. The table attached summarizes the unit production times and the centers required by each of the alternate methods of producing each product.

The unit cost of widgets produced using Methods 1, 2, and 3 are $1.35, $1.28, and $1.47, respectively. Similarly, the unit cost for gadgets using Methods 1, 2, 3 and 4 are $1.14, $1.19, $1.26, and $1.16, respectively. The weekly demand for widgets and gadgets are 320 and 250, respectively, and each machining center is available for 80 hours per week at most. Formulate and solve a linear programming problem to find the least cost weekly production schedule that will satisfy the weekly demand. Summarize the number of widgets and gadgets produced by each machining method in the least cost solution.