A pharmaceutical company, named “XYZ”, plans to deliver trials to three different clinics (C1, C2, and C3). The trials are used for the emergency treatments so XYZ must fulfill all trial requirements. XYZ has 3 deliver trucks. Each truck can ship 200 trials per trip. Depending on the distance between XYZ and its clinics, the shipping cost may be different. Usually, it takes a week to deliver, i.e., if we decide to deliver in Week 1, the clinic will receive the trials in Week 2 and the truck will be available in Week 2. Each clinic has a dedicated space for holding the left-over trials. The holding cost per trial is around ten cents per week. To simplify the question, XYZ can produce as many trials as we want in any week. Currently, XYZ just ship when the clinics don’t have any inventory. Though, it costs higher and sometimes the trials in the clinics may be out of stocks. XYZ asks our help and provide the following data. Please use the optimization skills learned in OR 541 and help XYZ improve the distribution plan.

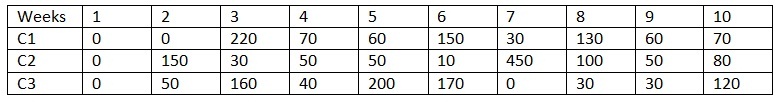

The demand data is as follows.

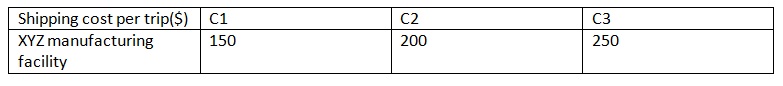

The shipping cost might depend on the distance. The given data is the shipping cost per trip.

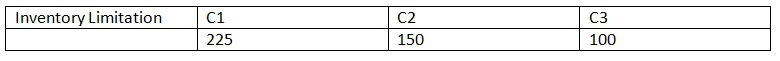

The space in the clinics is shown in the given table.

Please provide a report to manager that answers the following:

A) Formulate the problem to determine the distribution in order to minimize the total cost. Please provide a mathematical description of the model.

B) Follow the formulation in Part I and solve this problem using MPL as a Mixed Integer optimization problem. Please provide the .mpl file.

C) If we fix the truck deliver plan (not including the amount of trials in each trip), the problem will become a linear optimization problem. Please comment on the sensitivity of the solution you obtained in part B. to changes in cost coefficients.

D) Please comment on the sensitivity of the solution you obtained in Part C, i.e., to changes in the constraint data, e.g., to increase the inventory limitation.

E) Given this analysis, what is your recommendation to the company?

F) The actual demand data may not be known when we optimize. In XYZ, the actual demand may have +10% or -10% variation.

The manager would like to also consider this factor in the optimization model. Do you have any suggestion? How do we do?