Question 1: Can a factory be fast, dependable, flexible, produce high quality products and still provide poor service from the customer’s perspective?

Question 2: What do you understand by ‘order winners’ and ‘order qualifiers’? How can an organization identify such qualifiers?

Question 3: What do you understand by the term core competencies? Support your answer with an illustration of an organization and how that organization’s strategy is associated to its core competencies.

Question 4: Explain the input-transformation-output relationship found in your organization or unit or sub-unit.

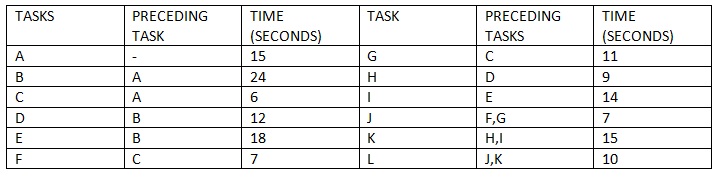

Question 5: Some tasks and the order in which they should be performed according to their assembly needs are shown in the given table. These are to be combined into workstations to make an assembly line. The assembly line operates 7-1/2 hours per day. The output needed is 1000 units per day.

i) What is the workstation cycle time?

ii) Balance the line by using the longest task time based on the 100-unit forecast, stating which tasks would be completed in each workstation.

iii) For (ii) what is the efficiency of your line balance?

iv) After production was started, Marketing realized that they understated demand and should increase output to 1100 units. What action would you take? Be precise in quantitative terms.