QUESTION 1:

The operations manager of a firm that produces frozen dinners from supermarkets about the firm's Fried Kenny dinners. The manager then asked her assistant, Jen, to investigate the matter and to report her recommendationsusing appropriate quality tools.

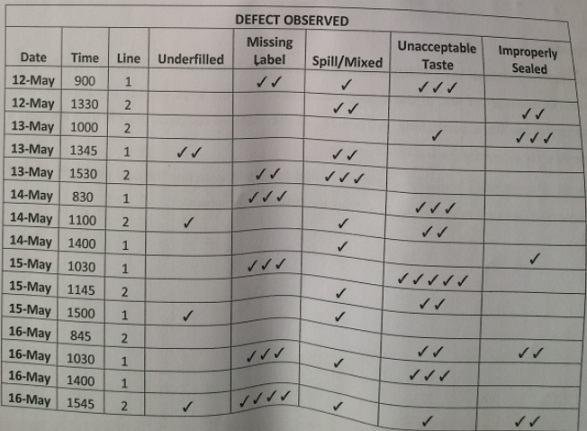

Jen's first task was to determine what problems were generating the complaints. The majority of complaints centered on five defects: underfilled packages, a missing label, spills/mixed items, unacceptable taste, and improperly sealed packages.

Next, she took samples of dinners from the two production lines and examined each sample, making note of any defects that she found. A summary of those results is shown in the table.

The data resulted from inspecting approximately 800 frozen dinners. What should Jen recommend to the manager?

Table: Defect observed

Required:

Question 1.1:

Given the five (5) defects observed, construct a Pareto diagram showing the number of defects observed at Fried Kenny with label and show the percentage according to each defect.

Question 1.2:

After identifying the most numbered of defects in Question 1.1, analyse and evaluate the most numbered detects combining Line 1 & Line 2 and recommend step by step process to Jen on how to reduce or eliminate the defect in the future.

Question 1.3:

After your recommendation, create a scatter diagram to prove that there are concrete relationship between the time when the defects were observed in relation to the number of defects found and discuss your findings.

QUESTION 2:

SCENARIO:

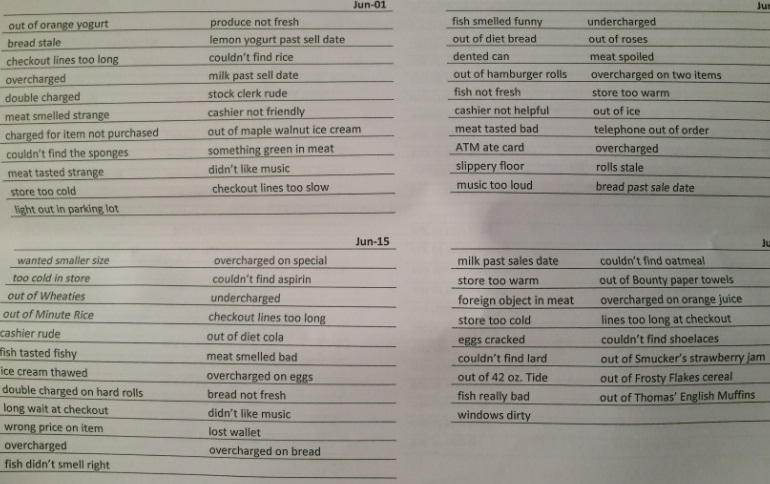

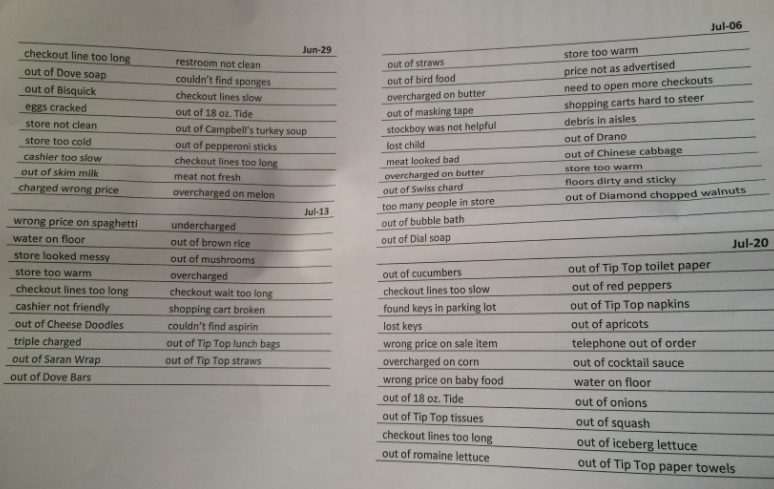

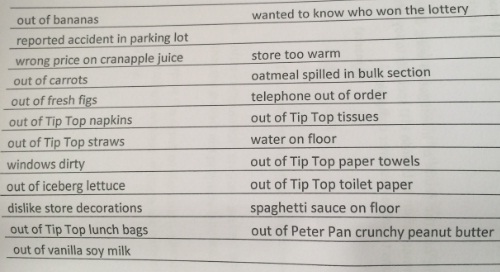

Lizardo LTD is a regional chain of supermarkets located in the Town Centre of Tumawini New Zealand. Joy Martin, manager of one of the stores, was disturbed by the large number of complaints from customers at her store, particularly on Tuesdays, so she obtained complaint records from the store's customer service desk for the last nine Tuesdays.

Given list of complaints below, you had been asked to help in analysing the data and make a Isit of recommendations for improvement to address the customer complaints.

Required:

Question 2.1: To be able to sort the similar complaints, you are required to categorize complaints, according to its similarity and nature of the problem. Create a check sheet in sorting the complaints and explain how did you sort the complaints accordingto its category.

Question 2.2: After sorting the complaints per category analyse and choose an appropriate tools (out of seven (7) basic quality tools for improvement) and explain why relation to the case.

you choose the appropriate tools in (3 marks)

Question 2.3: Create a Cause-and-Effect Diagram analysis focusing more on the top number of complaints that you have in Question 2.2. Provide at least 3 three causes and briefly discuss each causes and (4 marks) provide at least 2 possible solution for each.

Question 2.4: Create an analysis using a run chart showing the number of complaints received every Tuesday. Evaluate your result especially when Lizardo LTD implement changes on July 15 which reflects any improvement and discuss the level of complaints after.

Question 2.5: After applying all the methods and finding out the results of investigation using different tools for improvement, discuss your over-all recommendation to Lizardo LTD specially to Joy Martin and give at least four (4) significant recommendations to settle customer complaints.

Question 3:

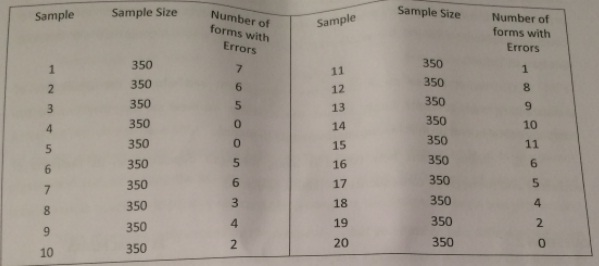

Completed forms from a particular department of bank were sampled a daily basis as a check against the quality of performance of that department. In order to establish a tentative norm for the department, one sample of 350 units was collected for each day 20 days, with these results:

a) Using a p-chart method with 95 percent confidence interval, calculate the following :

1. p

2. Sp

3. UCL

4. LCL

(You need to present a comprehensive computation )

b. After computation, create a p-chart and plot the 20 samples collected and make sure that the p chart are properly labelled.

c. Interpret the result of the chart, give comments if the process is in control or out of control and analyse if there are necessity to find the cause of such widespread variation if any.

Question 4:

They attempt to minimize both the likelihood of failure and the effect it will have,although the method of a coping with failure will depend on how serious its consequences are, an is to occ although could b occur. At be considered and how likely it At a minor level, every small error in the delivered product or service from the operation this type of 'failure'.

A) What do we mean about risk management and what is the significance of understanding such concept? Briefly discuss the activities involved on that may provide the company's total operation in achieving improvement?

B) Briefly discuss how failure is being managed depending on its likelihood of occurance and the negative consequences of failure.

Question 5:

Case study:

Slagelse Industrial Services (SIS) had become one of Europe's most respected die-casters of zinc, aluminium and magnesium parts and a supplier for hundreds of companies in many industries, especially automotive and defence. The company cast and engineer precision components by combining the most modern production technologies with precise tooling and craftsmanship. Slagelse Industrial Services (SIS) began life as a classic family firm set up by Erik Paulsen, who opened a small manufacturing and die-casting business in his hometown of Slagelse, a town in east Denmark, about 100 km southwest of Copenhagen. He had successfully leveraged his ski's and passion for craftsmanship over many years whilst serving a variety of different industrial and agricultural customers. His son, Anders, had spent nearly 10 years working as a production engineer for a large automotive parts supplier in the UK, but eventually returned to Slagelse to take over the family firm. Exploiting his experience in mass manufacturing, Anders spent years building the firm into a larger-scale industrial component manufacturer but retained his father's commitment to quality and customer service. After 20 years he sold the firm to a UK-owned industrial conglomerate and within 10 years it had doubled in size again and now employed in the region of 600 people and had a turnover approaching €200 million. Throughout this period the firm had continued to target their products into niche industrial markets where their emphasis upon product quality and dependability meant they were less vulnerable to price and cost pressures. However in 2009,in the midst of difficult economic times and widespread industrial restructuring, they had been encouraged to bid for higher volume, lower margin work. This process was not very successful, but eventually culminated in a tender for the design and production of a core metallic element of a child's toy (a 'transforming' robot).

Interestingly the client firm, Alden Toys, was also a major customer for other businesses owned by SIS's corporate parent. They were adopting a preferred supplier policy and intended to have only one or two purchase points for specific elements in their global toy business. They had a high degree of trust in the parent organization and, on visiting the SIS site, were impressed by the firm's depth of experience and commitment to quality. In 2010, they selected SIS to complete the design and begin trial production.

'Some of us were really excited by the prospect . . . but you have to be a little worried when volumes are much greater than anything you've done before. I guess the risk seemed OK because in the basic process steps, in the type of product if you like, we were making something that felt very similar to what we'd been doing for many years.' (SIS Operations Manager)

'Well, obviously we didn't know anything about the toy market but then again we didn't really know all that much about the auto industry or the defence sector or any of our traditional customers before we started serving them. Our key competitive advantage, our capabilities, call it what you will, they are all about keeping the customer happy, about meeting and sometimes exceeding specification.' (SIS Marketing Director)

The designers had received an outline product specification from Alden Toys during the bid process and some further technical debt in afterwards. Upon receipt of this final brief, a team of engineers and managers confirmed that the product could and would be manufactured using an up-scaled version of current production processes. The key operational challenge appeared to be accessing sufficient (but not too much) capacity Fortunately, for a variety of reasons, 515's parent company was very supportive of the project and Promised to underwrite any sensible capital expenditure plans. Although this opinion of the nature Alden Toys of the production challenge was widely oys accepted throughout the firm (and shared by and SIS's parent group), it was left to one specific senior engineer to actually sign both and th the final bid. By early 2011, the firm had begun a trial period of (tavol; technical completion documentation. we production. Unfortunately, as would become clear later, during this design validation process sis had effectively sactioned a production method that would prove to be entirely inappropriate for the toy market; but it was not until 12 months later that any indication of problems began to emerge.

Throughout both North America and Europe, individual customers began to claim that their children had been poisoned whilst playing with the end product. The threat of litigation was quickly levelled at Alden Toys and the whole issuerapidly became a 'full blown' child health care scare. A range of pressure groups and legal damage specialists supported and acted to aggregate the individual claims. Although similar accusitions had been made before, the litigants and their supporters focused in on the recent changes made to the production process at SIS and in particular the role of Alden Toys in managing their suppliers.

Its all very Well claiming that you trust your suppliers but you simply cannot have the same level of control over another firm in another country. am afraid that this all comes down to simple economics, that Alden Toys put its profits before children's health. Talk about trust . . . parents trusted this firm to look out for them and their families and have every right to be angry that boardroom greed was more important? (Legalspokesperson for US litigants when being interviewed on UK TV consumer rights show).

Under intense media pressure, Alden Toys rapidly convened a high-profile investigation into the source of the contamination. It quickly revealed that an 'unauthorized' chemical had been employed in an apparently trivial metal cleaning and preparation element of the SIS production process. Although, when interviewed by the US media, the parent firm's legal director emphasized there was ' no causal link established or any admission of liability by either party ', Alden Toys immediately withdrew their order and began to signal an intent to bring legal action agaist SIS and its parent. This action brought an immediate end to production in this part of the operation and the inspection (and subsequent official and legal visits) had a crippling impact upon the productivity of the whole site. The competitive impact of the failure was extremely significant. After over than a third (39 per cent) of the factory's output. In addition to major cash-flow implications, the various investigations took up lots of managerial time and the reputation of the firm was seriously affected. As the site operations manager explained, even their traditional customers expressed concerns.

'It's amazing but people we had been supplying for 30 or 40 years were calling me up and asking "what's going on?" and that they were worried about what all this might mean for them ..

QUESTIONS

1: In implementing the said strategy, SIS experience control problems before and after the implementation, critically evaluate the control problems that they encounter, and you may classify them according to their Supply networks. Process Technology, Capacity and Development and Organisation?

2. Identify and briefly discuss the operational risks of SIS faced when deciding to become a strategic supplier for Alden Toys? Classify them according to the causes of risk discussed on the class and critically evaluate your basis of classification.