Part 1: Casting – Metal Forming

1. Name the TWO main metals that are used in the pressure die casting industry and explain the main difference in the casting ability of the two metals.

2. With the aid of a sectional diagram name all the major parts of a gravity sand casting mould.

3. Name TWO processes that can be used to manufacture an Aluminium alloy piston for an internal combustion engine. (Neglect any machining operations)

a. Explain TWO major advantages and disadvantages of both the processes identified in the above question.

b. Describe a suitable method of checking the pistons for porosity.

4. Briefly explain with the aid of a simple sketch the purpose of using both internal and external “Chills” in the casting process.

5. Describe TWO methods used to overcome spring back when bending flat metal sheet.

6. Explain the term “Anisotropy” when associated with the bending of sheet metal; use a sketch to aid your explanation.

7. Use a flow diagram to explain the manufacturing processes used to make seamless Aluminium tubing.

a. State why the above process cannot be used to manufacturing seamless Stainless steel tube.

b. When manufacturing Stainless steel tubing how can the problem identified above be overcome.

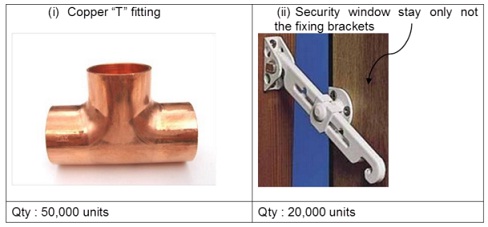

8. Name ALL the most economical manufacturing processes required to manufacture the two components shown below. The finished components must be fully functional.

9. Describe the process that would be the most suitable for manufacturing a 10 litre hydraulic oil accumulator that is required to operate at a working pressure of 450 bars.

10. State TWO reasons why the Rotary swaging process has replaced the Machining process in some of the manufacturing plants around the world.

Part 2 - Machining

11. With the aid of a simple sketch describe all the movements of a 5 axis Machining centre.

12. List TWO advantages of using the Oblique cutting method.

13. Give an example of THREE components that have used the broaching process. Use a sketch/picture of each component and indicate on the sketch/component the surfaces that have been produced by the broaching process.

14. Calculate the spindle speed (Rpm) required by a CNC milling machine when drilling a 1 mm diameter hole to a depth of 10 mm in Aluminium alloy using a solid carbide drill. State any other factors that may influence the calculated spindle speed.

15. Describe TWO methods used to overcome the difficulty of machining continuous chip forming materials.

16. With the aid of a simple sketch explain the difference between Climb and Conventional milling.

a. Describe TWO advantages of climb milling.

b. Describe ONE disadvantage of climb milling.

c. Explain why Climb milling is machines.

17. Name TWO engineering components that have used a grinding operation during the process of being manufactured. State TWO reasons why the grinding operation was necessary.

18. Explain why it is bad practise to use a fluted thread tap to cut the thread in a hole that has been friction drilled in 2 mm plate.

19. Carbide tipped tools/inserts are common place in the majority of machining processes today. Briefly describe how these cutting tools are produced and the methods that have been used to increase their life.

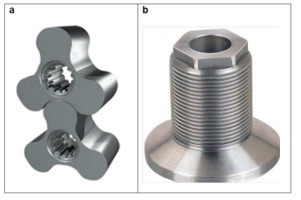

20. List ALL the machining operations required to manufacture the following two components shown below. Name a suitable machine tool that could be used to manufacture each component.

Part 3 - Welding - 3D Printing – Plastics - Coatings

21. Describe the difference between the Solid–State and Fusion welding processes.

a. State TWO advantages and disadvantages for each of the above processes

b. Name THREE commonly used Solid–State and Fusion welding processes

22. Briefly describe with aid of a diagram the Flux-cored Arc Welding (FCAW) process. Explain TWO major advantages of using this process.

23. Explain the importance of the joint gap distance when joining metals with the brazing process.

24. Describe the advantages that may be gained by using the 3D printing process.

25. Explain the purpose of using support material when manufacturing a 3D model.

a. Describe how the support material is removed from the model after the manufacturing process is complete.

b. Explain how the surface finish texture manufacturing process.

26. Name and described the manufacturing process used to make the common plastic milk bottle, use a sketch to aid your explanation.

27. Carbon fibre is now being extensively used in the manufacturing industry.

a. State why the above process has superseded existing manufacturing processes.

b. Explain ONE major disadvantage of using the material.

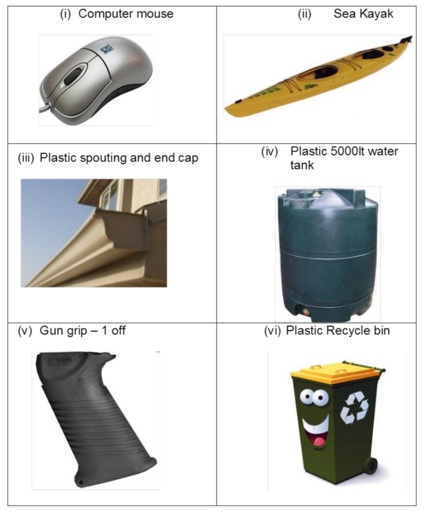

28. Name the most economical manufacturing processes required to manufacture the items shown below.

29. Briefly explain the importance of sustainable manufacturing.

a. Name TWO sustainable manufacturing processes.

b. Name TWO manufacturing processes that are not sustainable.

30. State TWO reasons why electro plating is used in the manufacturing industry.

a. Explain the difference between hard chrome plating and Decorative plating.

b. Can plastic be decorative chrome plated.