1. An aluminium rod is to withstand an applied force of 200 kN. To ensure a sufficient factor of safety, the maximum allowable stress on the rod is limited to 170 MPa (170MN/m2) with a strain of 0.0025mm.mm-1. The rod must be at least 3.8 m long but must deform elastically no more than 6 mm when the force is applied. Design an appropriate rod.

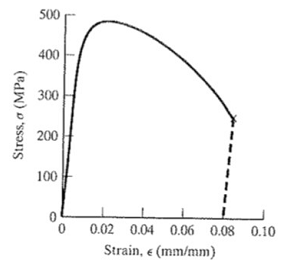

2. From stress-strain diagram below for Aluminium alloy, calculate the E, YS (σY) and UTS (σU), and percent elongation at failure.

3. A 10-mm diameter rod of carbon steel is subjected to a tensile load of 50,000 N, taking beyond its yield point (YS = 600 MPa and UTS = 750 MPa). Calculate the elastic recovery that would occur upon removal of the tensile load. E = 200 x 103MPa.

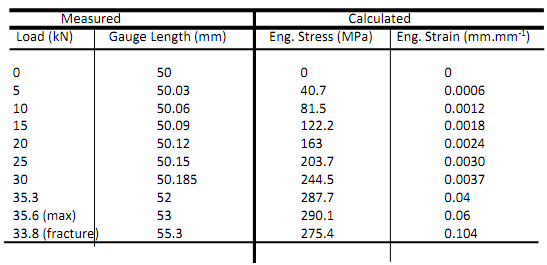

4. Table 1 below shows the results of a tensile test of a 12.5 mm diameter aluminium alloy test bar with original cross sectional area Ao = 122.7 mm2)

a. Convert the load-gauge length data in Table 1 to engineering stress and strain and plot a stress-strain curve

b. From the data in Table 1, calculate the modulus of elasticity of the aluminium alloy. Use the modulus to determine the length of a 1.25 m bar to which a stress of 210 MPa is applied.

c. Compare engineering stress and strain with true stress and strain for the aluminium alloy (on a - above), and determine the (i) maximum load and (ii) fracture. The diameter at maximum load is 12.3 mm and fracture is 9.85 mm.