The given information is available for three MPS (Master Product Scheduling) items:

Product A: An 80 unit order is to be started in Week 3.

A 55 unit order is to be started in week 6.

Product B: A 125 unit order is to be started in week 5

Product C: A 60 unit order is to be started in week 4.

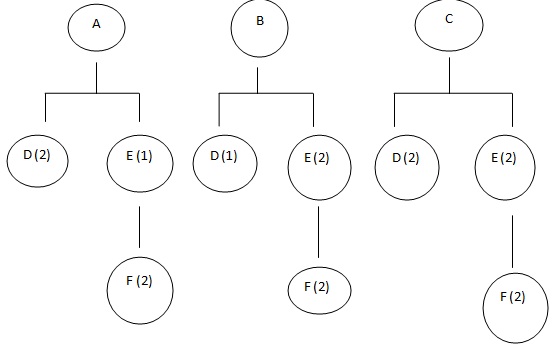

Build a material requirements plan for items D, E and F. The BOMs (Bill of Materials) are shown in the figure below, and the data from the inventory records are shown in table below. (Warning: The safety stock requirement applies to item F. Be sure to plan a receipt for any week in which the projected on hand inventory becomes less than the safety stock).

Data Category D E F

Lot Sizing Rule FOQ = 150 L4L POQ (P=2)

Lead Time 3 weeks 1 week 2 weeks

Safety Stock 0 0 30

Scheduled Receipts 150 (week3) 120 (week 2) None

Beginning inventory 150 0 100