Problem 1

Work through TALPAC 10 Basics. Answer the set of questions at the end of tutorial module.

Problem 2

- How does the optimum number of HD785-5s at mid-life of the quarry vary with?

- Coefficient of traction?

- Rolling resistance for poorly managed haul road?

- Slope of the main (400 m @ 10%) ramp?

- How does the optimum number of HD785-5s vary between the given periods if production cost increases at a rate of 15% per year with mid-life of the quarry as the base year?

- How does depth of the quarry affect productivity of the operation?

- How does material density affect productivity of the operation?

Produce necessary plots to support your answers.

Problem 3

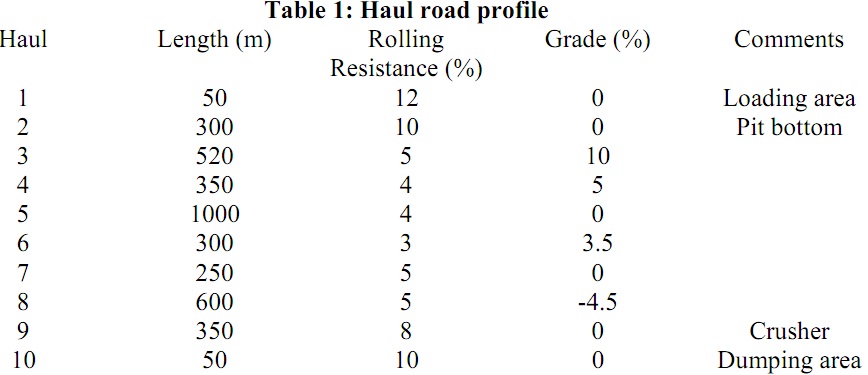

A gold mine is proposing to develop a new open pit mine. The top soil will initially be removed by scraper and the remaining oxidised ore will be drilled, blasted and transported to a crusher dump site where the ore will be rechanneled by FEL into a crusher. The anticipated haul road profile for the first five years is provided in Table 1.

Management imposes the following speed limit at the pit:

- Within 50 metres of the shovel or crusher, the truck speed is restricted to 20 km per hr;

- When travelling down ramps, truck speed must not exceed 40 km per hr;

- A maximum of 45 km per hr truck speed elsewhere when a truck is loaded and 50 km per hr when empty.

The mining company has a long-standing relationship with Caterpillar and Komatsu companies. The mining company is considering CAT FEL with the following estimated data:

CAT FEL

Availability 0.90

Loading time (min) 0.50

Economic life (hrs) 45 000

Bucket fill factor 0.90

The mining company is also considering Komatsu rear dump trucks with the following estimated data:

Komatsu rear dump trucks

Dump time (min) 1.2

Availability 0.85

Spot time at loader (min) 0.55

Spot time at dump (min) 0.50

Economic life (hrs) 30 000

The loose density of blasted ore is 2.5t/m3 with 12% swell factor. The required annual run

Of mine ore production is 16x106 t.

Your task is to use TALPAC to determine and recommend

- A working roster for the pit

- CAT FEL type and its size

- Komatsu rear dump truck type and its size

- Loader and truck fleet size which meets the annual production target, taking in consideration both technical and economic factors

- Unit production cost

Make any reasonable assumption where necessary.