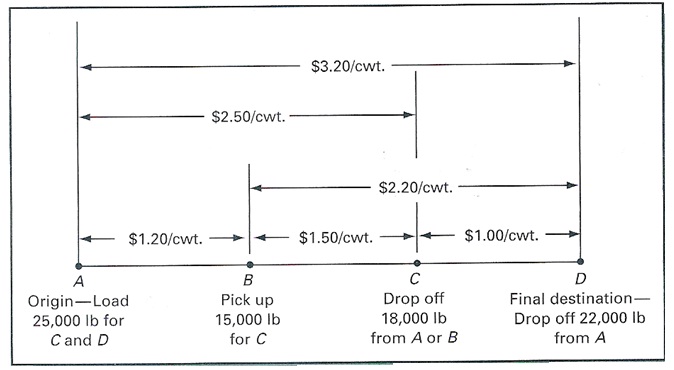

Problem 1. A traffic manager has two options in scheduling a truck to make multiple pickups and deliveries. The pick-up delivery problem is shown pictorially in figure. The traffic manager can ship the accumulated volumes as single shipments between the designated points or can use the stop-off privilege at $25 per stop for any or all portions of the trip. If the traffic manager wishes to minimize shipping costs, which alternative should be chosen? Assume that the final destination point incurs the stop-off change?

|

Transport Mode

|

Transit Time, Days

|

Rate, $/Unit

|

Shipment Size, Units

|

|

Rail

|

16

|

25.00

|

10,000

|

|

Piggyback

|

10

|

44.00

|

7,000

|

|

Truck

|

4

|

88.00

|

5,000

|

Problem 2. The Wagner Company supplies electric motors to Electronic Distributors, Inc.on a delivered-price basis. Wagner has the responsibility for providing transportation. The traffic manager has three transportation service choices for delivery-rail, piggyback, and truck. He has compiled the information in the attached file. Electronic Distributors purchases 50,000 units per year at a delivered contract price of $500 per unit. Inventroy-carrying cost for both companies is 25 percent per year. Which mode of transportation should Wagner select?

The next two problems are Inventory Policy Decision problems.

Problem 3. Helen's Secretarial School trains young people in word processing and other secretarial skills. Tuition for the course is $8,500, but she will rebate up to 10 percent of the fee annually until the graduate receives a job. Average annual demand for her graduates is 300 per year. (Note: Product Value and setup costs are the same.)

a. How many potential secretaries should Helen admit per class?

b. How many times per year should she offer the course?

Problem 4. A computer-supply mail order house has a memory chip in inventory that it sells to customers around the country. A Japanese manufacturer supplies the item using airfreight. It has the following characteristics...Average annual demand = 3,200 units; Replenishment Lead Time = 1.5 weeks; Carry Costs = 15% per year; Purchase price, delivered = $55 per unit; Procurement ordering costs = $35 per unit.

a. Design a reorder point method of control for this item.

b. What are the annual ordering and annual carrying costs if your design is used?

c. Suppose that the lead time stretches to three weeks, so that the ROP > Q*. What adjustments would you suggest making in the control policy?