Question 1:

a) Describe the difference between batch repetitive flow line and mixed model repetitive flow line.

b) Distinguish between the terms manufacturing strategy and corporate strategy as applicable to production organization of your preference.

c) Manufacturing Policy is the outcome of translating corporate strategy to a long range plan for the production function of an organization. Describe the above statement with appropriate examples.

d) Explain how you would coordinate the product life cycle with the manufactory system life cycle for best outcomes.

Question 2:

a) Why would a make to stock manufacturer wish to become make to order? What trends in nowadays society contribute to the ability and/or need to be making to order?

b) What basic questions should any manufacturing organization attempt to answer irrespective of its size, process or type of product?

c) Compare and contrast the production plan with the business plan.

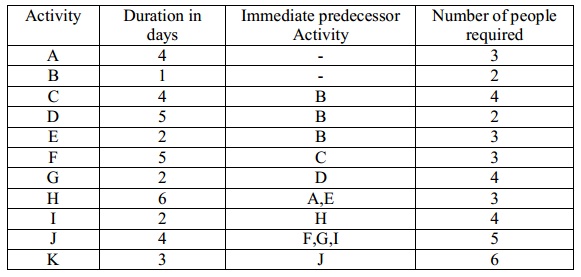

Question 3: XYZ Ltd is a company, which is included in introducing different industrial machineries to the local market. Currently the company is planning to introduce a new hydraulic press machine. The schedule of activities in manufacturing the machine, their duration and the respective manpower necessity for the project is shown in table below:

The cost per man-day is Rs. 1000.00. Activities G and I can’t be done simultaneously due to resource constraints.

You are required to:

a) Draw up a network to represent the above schedule and recognize the critical activities. What is the shortest time needed to complete the job?

b) Draw up a chart to show the manpower needed for each day for the duration of the job and estimate the cost if the job is to be completed in the shortest possible time.

c) If the number of people available is limited to a maximum of 10 on any given day, what minimum adjustments you would make in the chart so prepared, in response to above part of the question.

Question 4:

a) What is an operation process chart and what are its drawbacks?

b) Why is the flow diagram superior to both operation process chart and flow process chart in layout planning?

c) What kind of location would you recommend for an industry which is hazardous and as well causes a lot of pollution? Explain your answer.

d) List out the factors affecting plant location.