Question1. Part A

A compressor installed at a wharf (for loading container ships) is able to give 6 bar.g pressures into the pressure receiver. The compressor is moved to a site that is 5000 ft above sea level (atmospheric pressure 0.85 bar.a) in the mountains. What is the revised discharge pressure (guage pressure) of the compressor?

Assume there is no change in temperature.

Part B

Is the assumption of change in temperature valid for calculating the discharge pressure of the compressor?

Part C

The temperature at the wharf is 35 oC and in the mountains is 19 oC, what is the reduction in volumetric output from compressor?

Questio2.

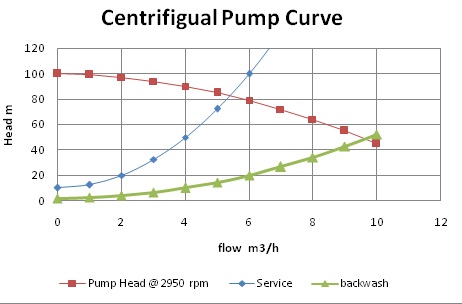

The system on site is a pressure sand filter, with a service curve. The filter is backwashed using the feed pump, at a higher flow rate, shown as backwash curve.

Service duty point: 3 m3/h

Backwash duty point: 9 m3/h

Part A

What is the speed of the pump to achieve the service and backwash flow rates?

Part B

What would be the best way to control the speed of the pump? Why?

Part C

The pump is set up as a fixed speed constant pressure system (pump runs once system pressure reaches 550 kPa, turns off, when pressure drops to 450 kPa plant re-starts) to maintain a system pressure of 500 kPa at the discharge of the pump. What would be the service and backwash rates from the pump?

Question3.

A pump station has been designed to lift water out of a 6 metre deep pit (vented to atmosphere) via a centrifigual pump mounted at ground level.

Liquid conditions 20 OC

Suction pipe work losses 2.0 metres

NPSH safety factor 5.0 kPa

Vapor pressure @ 20oC 0.25 metres

Part A

Calculate the Net Positive Suction Head (NPSH) for the system?

Part B

In summer the liquid temperature rises to 60 oC, this changes the water vapor pressure to 2.05 metres. What is the revised NPSH for the higher water temperature?

Part C

Pressure loss in the suction pipe work is directly proportional to water veloicty in the pipe work squared, which is inversely proportional to suction pipe work diameter squared.

Question4.

We have a reciprocating compressor operating at 800 rpm. Suction pressure and discharge pressure are held constant by other systems that have nothing to do with the compressor. We increase the speed from 800 to 840 rpm (a 5% increase).

Part A

What is the change in flow rate through the compressor Flow increases by (840/800) or 1.05, or 5% increase?

Part B

What is the change in pressure rise through the compressor?

Part C

What is the change in power that must be delivered to the compressor?

Question5.

We are operating a centrifugal compressor. The gas composition does not change during this excursion. While holding suction pressure and flow rate constant, the inlet temperature rises. What would you expect to happen to the discharge pressure, and why?